|

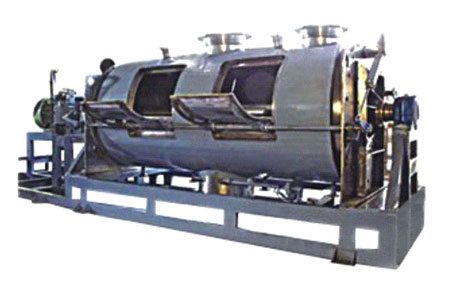

S.S Enginnering Plough Shear Mixer has a horizontal cylindrical shape with flat end

plates. The main shaft passes through the axis of the vessel and is supported at the

end plates in specially designed bearing housing. The plough shaped mixing elements

are arranged concentrically on the main shaft. The clearance between the ploughs and

shell wall is minimum, to facilitate better mixing. |

| |

APPLICATION CHEMICALS

MINERALS

FOOD

BREAK LINING AND INDUSTRIAL GASKETS

GLASS INDUSTRIES

ANIMA FEED

FIRE EXTINGUISHING POWDER

FERTILIZERS

DYES AND INTERMEDIATES |

| |

WORKING PRINCIPLE

The Mixer consistes of a cylindrical shell, fitted with

series of ploughs rotated on the central shaft which

incorporates ploughing motion. This pattern results in

collisions and blending of both dry and wet materials.

Plough Shear Mixer is long term operation for various

applications like mixing, grinding, dispersion etc.

Multiple Choppers are fitted on the mixing vessel

between ploughs. Choppers can be with multiple

blades or simple depending on the applications..

They prevent lump formation and better mixing. For

controlling the mixing, the Chopper

motor can be

switched on and off independently.

|

|

|

|

| NOZZLES

Generally a feed inlet nozzle is provided at the top of the mixer with quick opening lid

Rotary valve, Butterfly valve etc. can be provided depending on application.

Discharge

nozzle is provided at the bottom of shell for discharging wet or dry material Operation

of Discharge door shall be operated manually. This can be pneumatic or hydraulic

depending on application. Besides this one or more Flat type Inspection doors can be

fixed, on the front side of the mixer.

|

| |

Jacket

Blender can be designed with jacket or without jacket for heading or cooling

application. |

| |

Vacuum / Pressure

The Equipment can be designed for pressure and vacuum application where in

solid/Liquid/gas phase reaction can be carried out. |

| |

Drive

Fluid Coupling is fitted in between motor and gear box to prevent shock loading on

gear box, prevents the drawing of large current by the motor and damage to the drive

elements due to frequent starting and stopping of motor. |

| |

CONTROL PANEL

On off switching for plough and chopper. Ammeter, Voltmeter, Temperature indicator

Pressure indicator Audio Visual Alarm are housed in the panel. |

| |

|

|

|

|

PLOUGH |

MULTIPLE

CHOPPER |

SERRATED

PLOUGH |

CHOPPER |

|

| |

|

| |